MUV - PUT TO LIGHT (PTL)

PROCESS

1. Batch Picking

Create a picking list for a set of orders, also known as 'order waves'.

2. Consolidated Picking

Perform the picking of the set of orders in the product storage area. This approach reduces travel and makes picking more efficient.

3. Classify

Distribute products to their destination/orders using the PUT TO LIGHT (PTL) system.

A light will indicate to the operator where a SKU should be placed and the quantity.

The system will indicate when an order is complete.

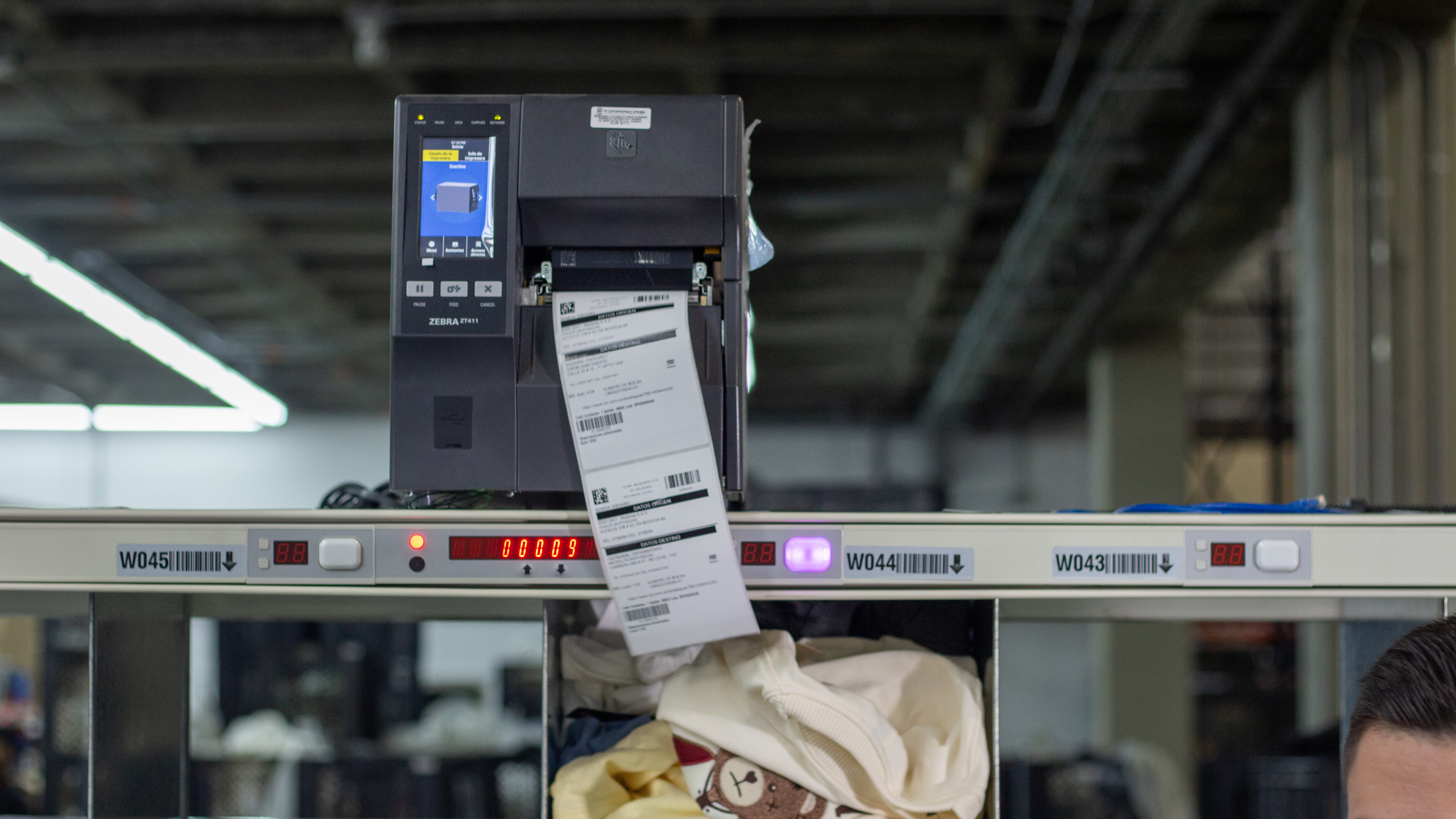

4. Seal

Automatically generate guides through integration with the carrier.

Print labels, invoices, packing lists, etc.

Pack and seal the orders in the respective packaging units.

DO YOU HAVE ANY

High number of orders.

High percentage of errors.

Complexity in the number of SKUs and lines per order.

Low productivity per hour per operator.

High operational costs.

Manual processes for labeling, packing lists, and transport guides.

MUV - PUT TO LIGHT (PTL)

Advantages

Intuitive and dynamic user experience.

It connects via an API and/or flat files.

Integrable and compatible with all ERP, WMS, MRP systems.

Virtual environment 'Digital Twin' to emulate the physical operation.

Easy hardware maintenance.

Increases operational efficiency: reduces travel, prevents errors, optimizes labor and movements.

Simplifies and standardizes picking tasks.

Management dashboards for key indicators of different processes for each user.

Software as a Service (SaaS) hosted on Microsoft Azure or on-premise.

Complementary

We complement our portfolio of solutions and services through partnerships with software providers and technology equipment vendors such as sorting sorters, automated order preparation systems, autonomous mobility robots, among others.

Request consultation

Tell us your needs and we will provide the best solution in the shortest possible time.