MUV - Supply Chain Consulting

Supply Chain Consulting: we diagnose and design distribution centers, raw material warehouses and supply network design; through consulting, simulation tools and mathematical modeling.

Together with the client we define: lay-out (areas), operation methodologies, equipment, infrastructure and level of automation. We always look for cost-efficient and scalable investments according to the growth plans of each company.

Do you have any of

Inadequate use of space.

Unuse of heights.

Unuse of heights.

Saturated or underutilized areas.

Excess inventories.

Bottlenecks in the operation.

Long distances.

Cross flows and insufficient areas.

Inadequate number of springs.

High transportation costs.

Time lost in the operation.

Muv- Supply Chain Consulting

Advantages

Better use of space.

Reduction of logistics costs.

Correct storage according to the type of product.

Handling, storage and dispatch methodologies.

Processes appropriate to the channels and product types.

Capabilities commensurate with projections and customer service.

Complementary

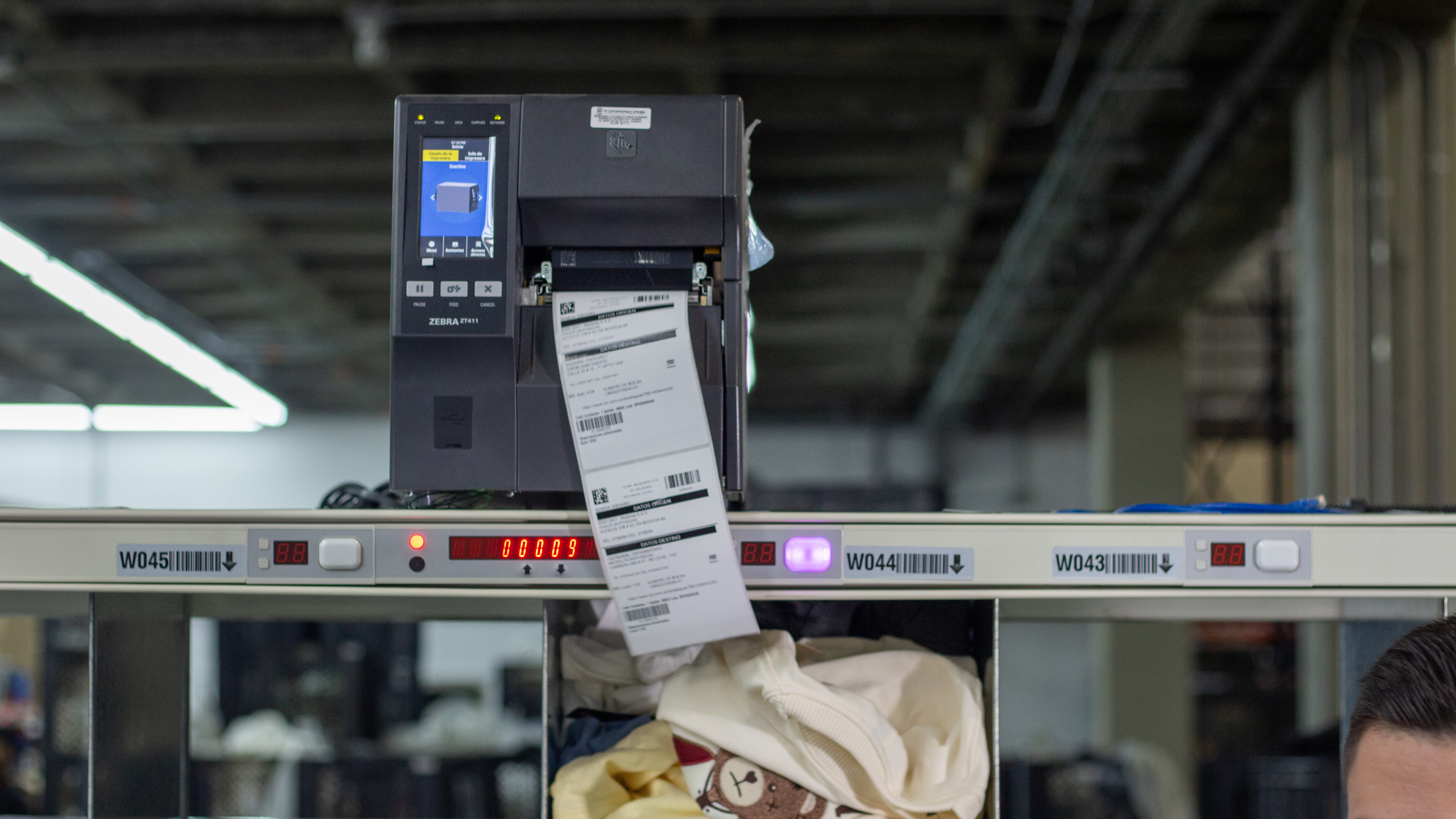

We complement our portfolio of solutions and services through partnerships with software and technology providers of equipment such as sorting sorters, automated order picking, autonomous mobility robots, among others.

Request consultation

Tell us your needs and we will give you the best solution in the shortest possible time.