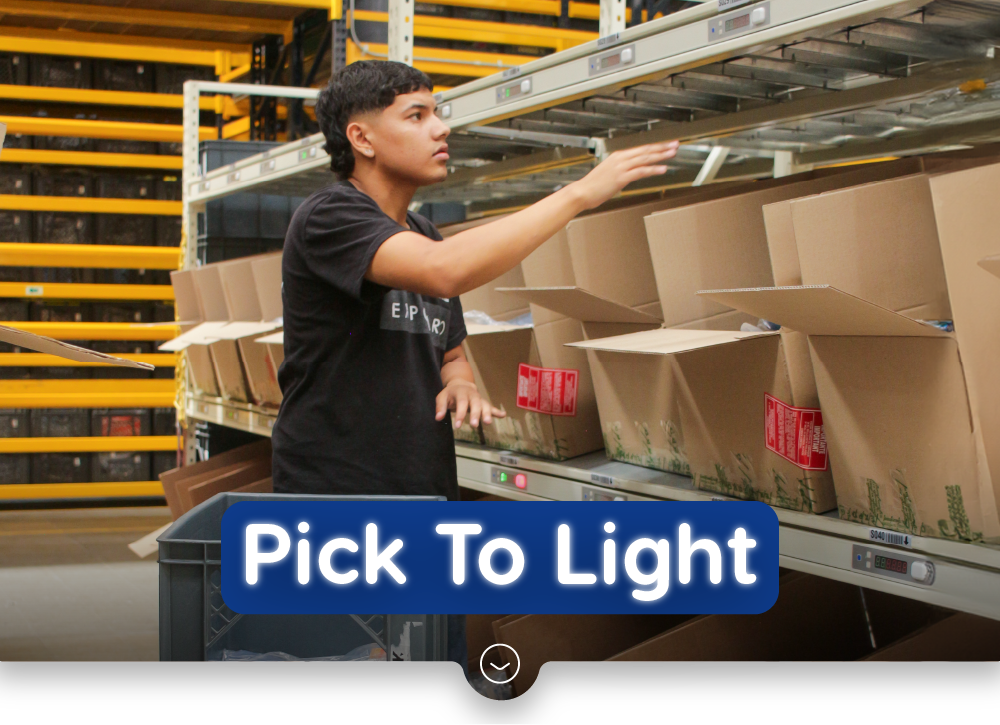

The Implementation of the Pick to Light System in the Supply Chain: Advantages and Benefits

In modern logistics, companies are constantly seeking ways to enhance efficiency and accuracy in their operations. One system that has gained prominence is Pick to Light (PTL). This system has become an essential tool for many companies, significantly improving productivity and accuracy in the picking process.

What is Pick to Light?

The Pick to Light system is a light-guided picking technology that optimizes the order picking process in warehouses and distribution centers. It uses LED lights and digital displays on shelves to guide workers to the correct product location and display the quantity to be picked.

Optimal Sectors for Implementing a Pick to Light System

Retailers and E-commerce:

With the exponential growth of e-commerce, the demand for speed and accuracy in order fulfillment is critical. Companies like Amazon and Walmart have implemented PTL systems to handle large order volumes with high precision.

Automotive Industry:

In automotive manufacturing, where thousands of components are handled, precision is vital. PTL ensures that the correct parts are picked and assembled, reducing errors and improving efficiency.

Food and Beverage Sector:

Freshness and traceability are crucial in this sector. Companies like Coca-Cola use PTL to ensure that the correct products are picked and shipped in the shortest possible time.

Pharmaceutical and Healthcare:

Precision is fundamental in fulfilling pharmaceutical orders. An error can have serious consequences. PTL helps reduce errors and increase efficiency in order fulfillment.

Importance of Implementing Pick to Light

Productivity Improvement:

Error Reduction:

Training Efficiency:

Increased Customer Satisfaction:

The implementation of Pick to Light is crucial for several reasons:

PTL allows workers to find and pick products more quickly, increasing productivity. According to a study by Logistics Management, companies can experience a 30-50% productivity increase after implementing PTL.

By visually guiding workers to the correct product location, PTL significantly reduces picking errors. A report by Modern Materials Handling indicates that error rates can decrease by up to 90%.

PTL is intuitive and easy to learn, reducing training time and costs. New employees can be quickly trained, which is beneficial during seasonal demand peaks.

Accuracy and speed in order delivery translate to higher customer satisfaction. A study by Aberdeen Group found that companies implementing PTL improved their delivery times by 20%.

benefits

By improving efficiency and reducing errors, companies can significantly save on labor costs and error correction.

PTL allows easy integration with other warehouse management systems (WMS), facilitating data collection and analysis for continuous process improvement.

Cost Reduction:

Continuous Improvement:

The system can be easily scalable and adapted to different warehouse and distribution center configurations.

Flexibility:

Speed:

PTL accelerates the picking process by providing clear and direct visual guidance, eliminating the need to search for products.

The Pick to Light system is an essential tool for improving efficiency, accuracy, and productivity in various industries. Companies looking to stay competitive in an increasingly demanding market should seriously consider implementing PTL as part of their supply chain management strategy. With tangible benefits and a quick return on investment, PTL not only improves internal operations but also significantly contributes to customer satisfaction. Moreover, it is a technology that is easy and quick to implement compared to other systems.